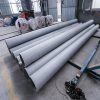

Product Parameters

| Product Name | Stainless steel boiler tube | |

| Type | Steel Pipe | |

| Outer diameter | Round Tube | 4mm-200mm |

| Square Tube | 10*10mm-100*100mm | |

| Rectangular Tube | 10*20mm-50*100mm | |

| Wall Thickness | 0.6mm-6.0mm | |

| Length | 1-6 meters, Length can be customized | |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. | |

| Surface | Black, Bright Polished, Rough Turning, Matt Surface Treatment, No. 4. BA, etc. | |

| Scope of Application | Common applications for stainless steel pipes include food processing, Textile operations, Breweries, Water treatment plants, Oil and gas processing, Fertilizers and pesticides, Chemical applications, Construction, Pharmaceuticals, Auto parts, etc. | |

| Certificate | ISO, SGS, BV, etc. | |

| Production Technology | Hot Rolling, Cold Rolling | |

| Edge Processing | Edging, Trimming | |

Stainless steel boiler tube Manufacturing

A welded stainless steel tube is produced through roll-forming strips or sheets of stainless steel into a tube shape and then welding the seam longitudinally. Welded tubing can be accomplished either by hot-forming and cold-forming processes. Of the two, cold forming results in smoother finishes and tighter tolerances. However, each method creates a durable, strong, steel tube that resists corrosion. The seam can be left beaded or it can be further worked by cold rolling and forging methods. The welded tube can also be drawn similarly to seamless tubing to produce a finer weld seam with better surface finishes and tighter tolerances.

Stainless steel boiler tube Benefits

- Cost-efficient

● Readily available in long lengths

● Fast lead times

Stainless steel boiler tube Applications

- Architectural applications

● Hypodermic needles

● Automotive industry

● Food and beverage industry

● Marine industry

● Pharmaceutical industry