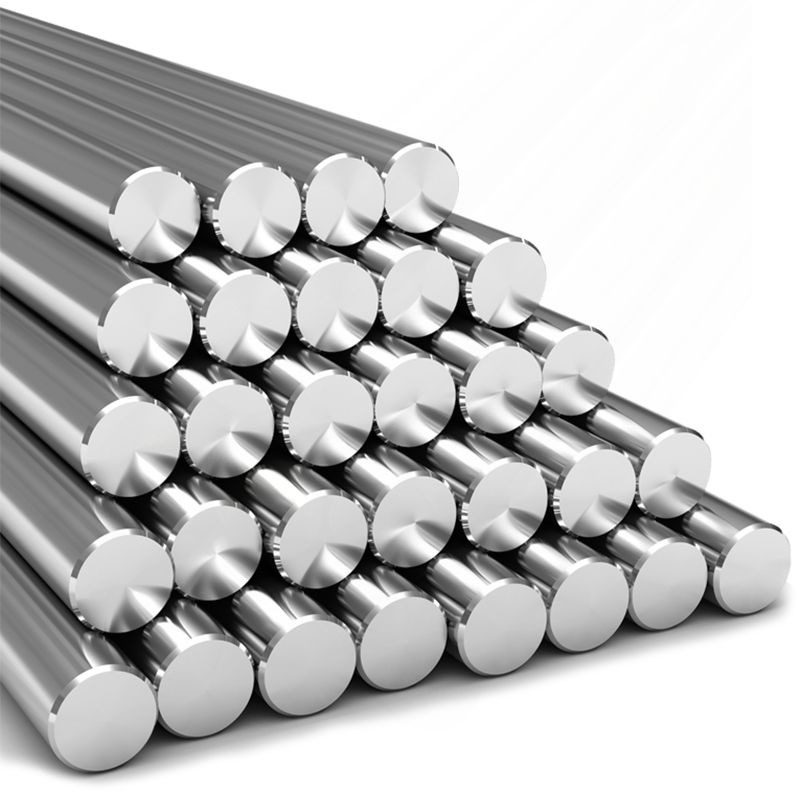

410 Stainless Steel Bar Description

410 stainless steel is a type of martensitic stainless steel with 11.5% chromium. 410 stainless steel bars have been quenched, tempered and polished to step up corrosion resistance. Unlike austenitic stainless steel, martensitic stainless steel is not as superior, which is why martensitic stainless steel requires a final heat treatment before manufacturing. This steel is hardened for maximum resistance to corrosion and heat. 410 stainless steel bars are a versatile and popular manufacturing parts in automotive manufacturing due to its many advantages. High strength is a key advantage making it ideal for applications requiring durability and wear resistance.

Product Parameters

| Product Name | 410 Stainless Steel Bar | |

| Type | Steel Bar | |

| Outer Diameter | Round Bar | 4mm-500mm |

| Hexagon Bar | 18mm-57mm (11/16″ to 2-3/4″) | |

| Square Bar | 18mm-47mm (11/16″ to 1-3/4″) | |

| Flat Steel | 1/2 “to 10”, Thickness: 2mm-150mm, Can provide customized | |

| Length | 1-6 meters, Length can be customized | |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. | |

| Surface | Black, Bright Polished, Rough Turning, Mattness Surface Treatment, No. 4. BA, etc. | |

| Scope of Application | Stainless steel bars are used in a variety of industries such as shipbuilding, Defense, Automotive, Textiles, Paper and pulp, Manufacturing, Cement, Heavy earthmoving equipment and construction, etc. | |

Chemical Composition

| C | Si | Mn | Cr | Ni | S | P |

| ≤ 0.15 | ≤ 1.0 | ≤ 1.0 | 11.5~13.5 | ≤ 0.5 | ≤ 0.03 | ≤ 0.04 |

Mechanical Properties

| Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

| ≥450 | ≥205 | ≥20 | ≤ 201HB |

Physical Performance

| Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(ΜΩ. cm) |

| 7.74 | 200 | 9.9 | 24.9 | 570 |