API 5L pipes are carbon steel pipes used for oil and gas transmissions. They include pipes manufactured in seamless and welded (ERW, SAW). The grades include API 5L Grade B, X42, X46, X52, X56, X60, X65, X70, X80 PSL1 & PSL2 onshore, offshore and sour services. API 5L is the implementation standard of steel pipe for pipeline transportation systems and specification for line pipe.

Our Supply Range for API 5L Pipe

Grades: API 5L Grade B, X42, X52, X56, X60, X65, X70, X80

Product Specification Level: PSL1, PSL2, onshore and offshore sour services

Outer Diameter Range: 1/2” to 2”, 3”, 4”, 6”, 8”, 10”, 12”, 16 inches, 18 inches, 20 inches, 24 inches up to 40 inches.

Thickness Schedule: SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, to SCH 160

Manufacturing Types: Seamless (Hot Rolled and Cold Rolled), Welded ERW (Electric resistance welded), SAW (Submerged Arc Welded) in LSAW, DSAW, SSAW, HSAW

Ends Type: Beveled ends, Plain ends

Length Range: SRL (Single Random Length), DRL (Double Random Length), 20 FT (6 meters), 40FT (12 meters) or, customized

Protection Caps in plastic or iron

Surface Treatment: Natural, Varnished, Black Painting, FBE, 3PE (3LPE), 3PP, CWC (Concrete Weight Coated) CRA Clad or Lined

Here we will do a brief introduction of API 5L pipe and related standard specifications with the below aspects:

Standard Scope

Manufacturing types

Different Grades (B, X42, X46, X52, X60, X65, X70)

Delivery condition (R, N, Q, M)

Product Specification Level (PSL1 and PSL2)

Material specifications (Chemical and Mechanical)

Test Methods

Tolerances on pipe diameters, wall thickness, out-of-roundness

Common defects

Line pipe history and milestones

Applications

API 5L Pipe Standard Scope

In API SPEC 5L 46th Edition, the standard scope is defined as: “Requirements for the manufacture of two product specification levels (PSL1 and PSL2) of seamless and welded steel pipes for use in pipeline transportation systems in the petroleum and natural gas industries. This standard does not apply to cast pipe.”

To summarize, API 5L pipe is the carbon steel pipe applied to the oil and gas transmission system. Meanwhile, other fluids such as steam, water, and slurry can also adopt the API 5L standard for their transmission purposes.

Different Manufacturing Types

API 5L specification covers the manufacturing types in welded and seamless.

Welded Type: ERW, SAW, DSAW, LSAW, SSAW, HSAW Pipe

The API 5L welded pipe common types are as follows:

ERW: Electric Resistance Welded, for pipe diameter normally under 24 inches.

DSAW/SAW: Double Submerged Arc Welding / Submerged Arc Welding, a substitute welding method of ERW for larger diameter pipes.

LSAW: Longitudinal SAW, for diameter up to 48 inches. Also called the JCOE manufacturing process.

SSAW/HSAW: Spiral Submerged Arc Welded / Helical SAW, pipe diameters up to 100 inches.

Check here for the differences between the ERW, LSAW, and SSAW pipes.

Seamless Type: Hot Rolled Seamless and Cold Rolled Seamless Pipe

Seamless manufacturing type is usually for small diameter pipes (typically under 24 inches).

(When the pipe diameter is less than 150 mm or 6 inches, the seamless steel pipe is more commonly applied than the welded steel pipe.)

There are also seamless pipes of large diameters. By using hot rolled manufacturing process, we can get seamless pipes with diameters up to almost 20 inches (508 mm). If you need seamless pipes with diameters above 20 inches, we can make them through hot expanding process, with maximum diameters up to 40 inches (1016 mm).

API 5L Pipe Manufacturing Development

In the earliest years, besides Seamless and ERW, SAW manufacturing technologies, the API 5L steel pipe also could be produced in furnace lap-welded (deleted in API 5L in 1962).

With the development of pipeline steel plate-making technology, pipe forming and welding technology has also seen significant improvement, so a lot of ERW pipes and SAW pipes have been used in pipeline constructions. When it comes to big-diameter steel pipes, SAW pipe gains a great advantage. With less raw material cost and simplified and uniform production procedures, welded steel pipe has taken the first place in oil and gas line pipe industries.

API 5L covers Grade B, X42, X46, X52, X56, X60, X65, X70, X80

API 5L steel line pipe adopts different steel grades, which are Gr. B, X42, X46, X52, X56, X60, X65, X70, X80. Some manufacturers are capable of manufacturing steel grades up to X100 and X120. As steel line pipes’ grades go higher, they have stricter control on the carbon equivalent control and higher mechanical strength performance.

Moreover, in the same grade, seamless and welded API 5L pipes have different chemical compositions, namely, welded pipes have stricter requirements and lower amounts of carbon and sulfur.

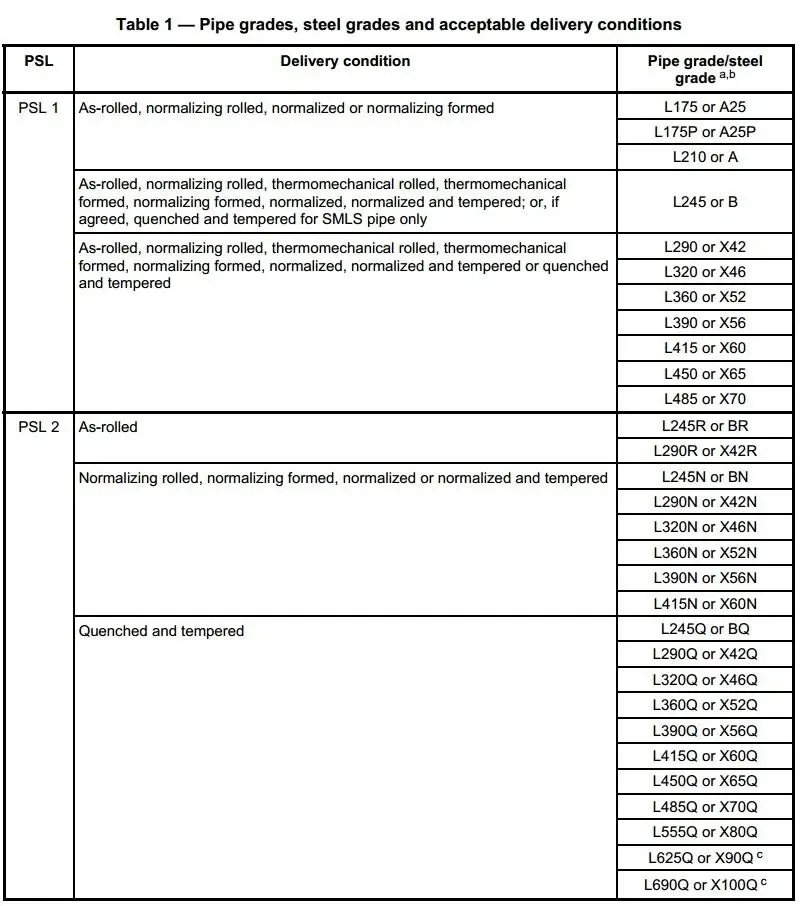

In terms of different delivery conditions, there are also As-rolled, normalizing rolled, thermomechanical rolled, normalizing formed, normalized, normalized and tempered, quenched and tempered.

Delivery Conditions for Each API 5L Grade

For intermediate grades, API 5L pipe grade shall be in one of the following description formats:

a. The letter L followed by the specified minimum yield strength in Mpa. For example, L290 (X42) means the minimum yield strength is 290 Mpa. In the case of PSL2 pipe, Suffix letters (R, N, Q, or M) shall be added to describe the delivery condition;

b. The letter X followed by a two or three digital number equal to the minimum yield strength in 1000 psi rounded down to the nearest integer and, for PSL2 pipe, the letter describing the delivery condition (R, N, Q, or M) consistent with the above formats.

Letter R: As rolled

Letter N: Normalizing rolled, Normalized formed, Normalized

Letter Q: Tempered and quenched

Letter M: Thermomechanical rolled or thermomechanical formed

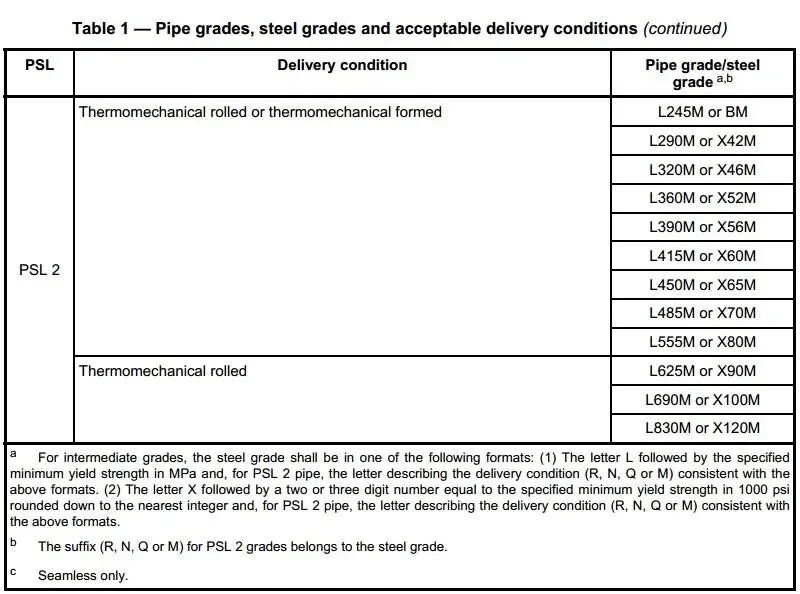

Letter S: Sour Services, comes with PSL2 pipe for NS, QS, and MS, eg API 5L X52MS, API 5L X65QS.

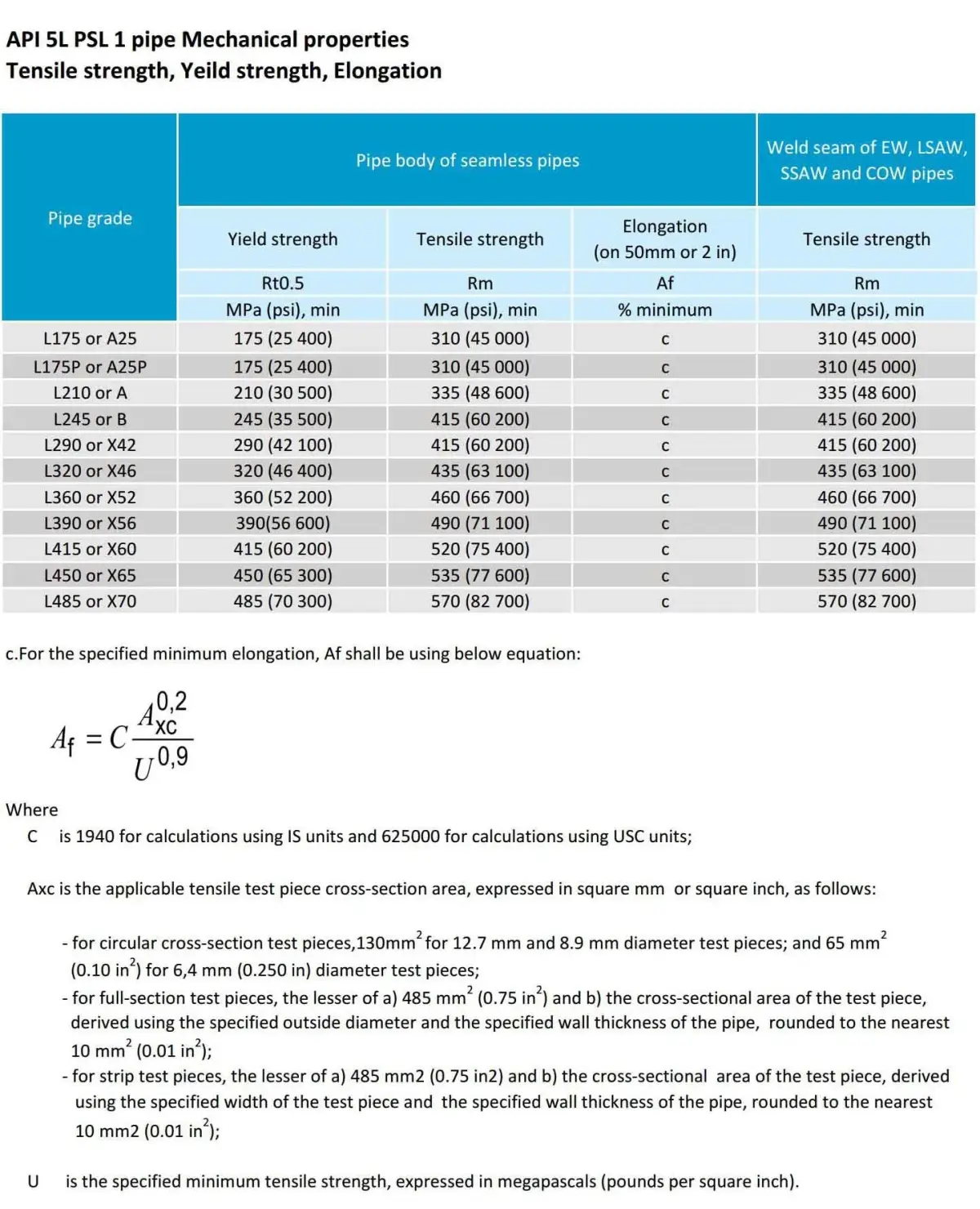

Product Specification Level (PSL1 and PSL2 in API 5L)

What is PSL

PSL is the abbreviation of product specification level, which includes PSL1 and PSL2. It also could be deemed as quality level.

PSL1 and PSL2 differences

Please click here for the differences between PSL1 and PSL2 pipes.

Requirement

PSL1 and PSL2 have not only different testing requirements but also different chemical composition and mechanical properties.

PSL1 has stricter requirements than PSL2 in terms of chemical composition, tensile properties, impact test, nondestructive testing, and other indicators.

For more details, please click here for Differences between API 5L PSL1 and PSL2.

Impact Test

PSL1 does not require an impact test, while it is required for PSL2 (except X80).

Non-destructive Test

PSL1 does not require a non-destructive test, while it is required for PSL2.

(NDT: Non-destructive inspection and testing uses radiographic, ultrasonic, or other methods (not breaking the material) in API 5L standard, to reveal pipe defects and imperfections.)

API 5L Pipe Data Sheet Specification

API 5L Pipe Data Sheet specification including chemical composition and mechanical properties for PSL1 and PSL2 pipe.

Chemical Composition

a. If C > 0.12%, CEIIW limits shall be applied; If C ≤ 0.12%, CEPCM shall be applied.

b. For each reduction of 0.01% for maximum C, an increase of 0.05% maximum Mn is permissible, up to a maximum of 0.20%.

c. Al ≤ 0.060%; N ≤ 0.012%; Al/N ≥ 2:1 (titanium-killed or titanium-treated steel not applicable); Cu ≤ 0.35% (Cu ≤ 0.10% if agreed); Ni ≤ 0.30%; Cr ≤ 0.30%; Mo ≤ 0.15%; B ≤ 0.0005%.

d. For seamless and welded pipes, Ca ≤ 0.006%; For welded pipe if Ca is added by intention unless agreed, Ca/S ≥ 1.5 in case S > 0.0015%.

e. For SMLS pipe maximum limit for S could be increased to ≤ 0.008%, and in case welded if agreed to ≤ 0.006%. For higher S content in the welded pipe, lower Ca/S ratios maybe agreed.

f. Nb + V ≤ 0.06%, unless otherwise agreed.

g. Nb + V + Ti ≤ 0.15%.

h. In case seamless pipe, listed CEPCM value could be increased by 0.03.

i. Mo ≤ 0.35% in case agreed.

j. Cr ≤ 0.45% in case agreed.

k. Cr ≤ 0.45% and Ni ≤ 0.50% in case agreed.

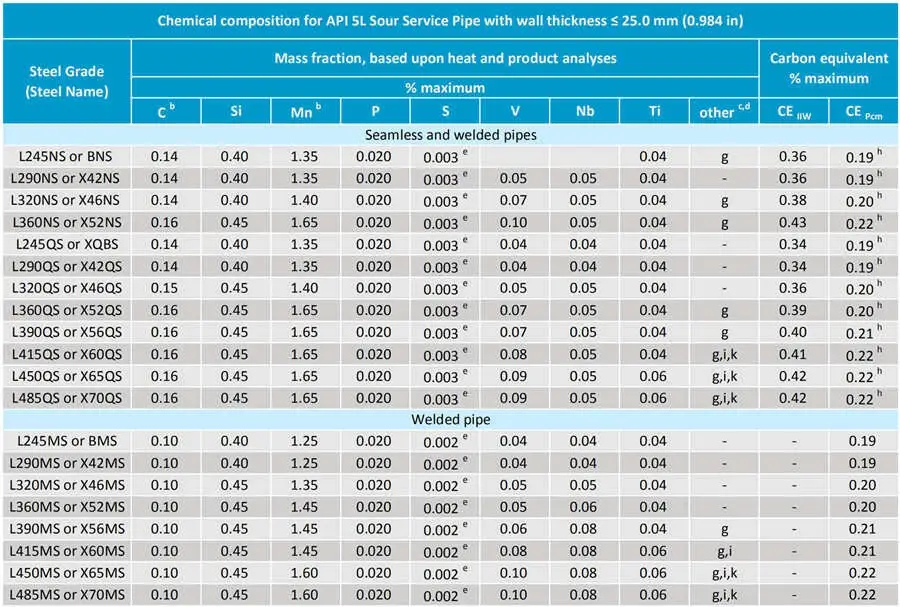

Tensile and Yield strength

API 5L Line Pipe Test Methods

Hydrostatic Test

a. Jointers need not be hydrostatically level, provided that the portions of pipe used in making the jointers were successfully hydrostatically tested prior to the joining operation.

b. Except in the previous situation, the pipe shall withstand the hydrostatic test without leakage through the weld seam or the pipe body.

Bend test

Cracks should not occur in any part of the sample and opening of weld shall not occur as well.

Please Note: For all bend tests, the weld extends to 6.4 mm (0.25 in) on each side of fusion line.

Flattening Test

The flattening test method is used to verify the deformation performance of line pipe to the specified size and display its defects. According to the stress and deformation characteristics of the specimen during the flattening process, the flattening test shall show the resistance to longitudinal cracking and circumferential cracking of the pipe and display its internal defects and surface defects.

Other than the above three common tests, there are other tests that are required in each circumstance.

Guided-bend test

CVN impact test for PSL2 pipe (including pipe body tests, pipe weld and HAZ tests)

DWT test for PSL2 welded pipe

Surface Conditions, Imperfections and Defects Appearances

All API 5L pipes shall be free from defects, cracks, sweats and leaks.

More defects as:

Undercuts in SAW and COW pipes.

Arc burns

Laminations

Geometric deviations

Hard spots

Other surface imperfections (Defects depth more than 0.125 thickness or ≤ 0.125 wall thickness refers to Clauses C in API 5L.)