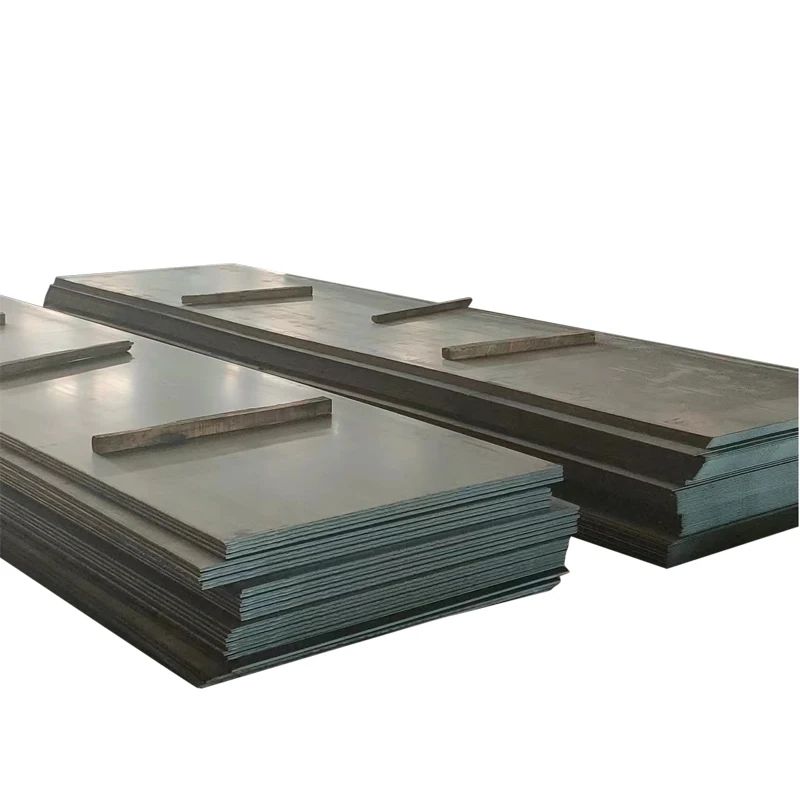

1023 Cold Rolled Steel Plate

1023 cold rolled steel plate is made of low-carbon alloy steel designed for use in applications that require excellent machinability and formability. This type of steel comes with outstanding weldability and machinability, making it an ideal choice for various applications. Its composition mainly includes iron, carbon, and manganese. 1023 steel plate does not have strong heat resistance compared to other steels due to its low carbon content; therefore it should not be used for applications requiring high temperature operation unless proper heat treatments are applied beforehand such as tempering or annealing.

Product Parameters

| Product Name | 1023 Cold Rolled Steel Plate |

| Production Process | Hot Rolling, Cold Rolling |

| Material Standards | AISI, ASTM, ASME, DIN, BS, EN, ISO, JIS, GOST, SAE, etc. |

| Width | 100mm-3000mm |

| Length | 1m-12m, or Customized Size |

| Thickness | 0.1mm-400mm |

| Delivery Conditions | Rolling, Annealing, Quenching, Tempered or Standard |

| Surface Process | Ordinary, Wire Drawing, Laminated Film |

Chemical Composition

| Element | Content (%) |

|---|---|

| Iron, Fe | 99.06-99.51 |

| Manganese. Mn | 0.30-0.60 |

| Carbon, C | 0.19-0.25 |

| Sulfur, S | ≤ 0.050 |

| Phosphorous, P | ≤ 0.040 |

Mechanical Properties

| Mechanical Properties | Metric | Imperial |

|---|---|---|

| Tensile strength | 425 MPa | 61600 psi |

| Yield strength | 360 MPa | 52200 psi |

| Shear modulus | 80.0 GPa | 11600 ksi |

| Bulk modulus | 140 GPa | 20300 ksi |

| Elastic modulus | 190-210 GPa | 27557-30458 ksi |

| Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

| Elongation at break | 15% | 15% |

| Reduction of area | 40% | 40% |

| Hardness Brinell | 121 | 121 |

| Hardness, Knoop | 140 | 140 |

| Hardness, Rockwell B | 68 | 68 |

| Hardness, Vickers | 126 | 126 |

| Machinability | 65 | 65 |