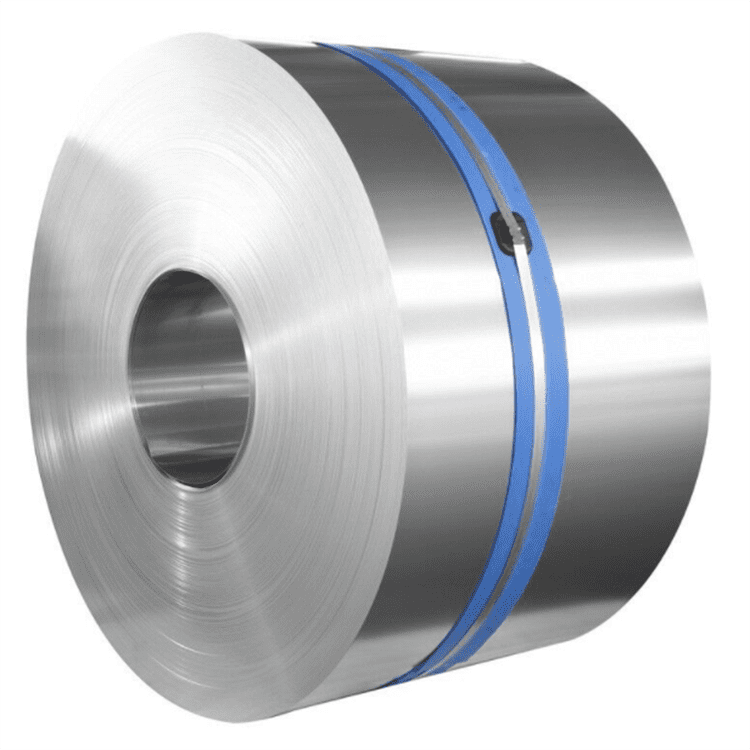

201 Stainless Steel Coil/Strip Description

201 stainless steel coil is composed primarily of iron with around 18% chromium and less than 0.15% carbon. It also includes small amounts of manganese, nickel, silicon, nitrogen, and copper. It has higher formability than the 300 series grades. Moreover, it can be hardened by cold working processes but cannot be heat-treated like 304 or 316 grades. 201 is a high manganese and low nickel stainless steel with low nickel content and corrosion resistance. It is widely used in various tabletops, countertops, kitchenware, outdoor decoration engineering, urban decoration industry and low-grade household products. It is also used in medical instruments and automotive parts that require flexibility while maintaining strength under pressure.

Product Parameters

| Product Name | 201 Stainless Steel Coil/Strip |

| Type | Steel Coil/Strip |

| Thickness | 2.5mm-10.0mm |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. |

| Width | 610mm-2000mm |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. |

| Surface | BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

| Scope of Application | Widely used in high temperature and electrical industry, medical equipment construction, chemical, food industry, agriculture and ship parts, food and beverage packaging, Kitchen supplies, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs and screens, etc. |

| Certificate | ISO, SGS, BV, etc. |

| Production Technology | Hot Rolling, Cold Rolling |

| Edge Processing | Edging, Trimming |

Chemical Composition

| C | Si | Mn | Cr | Ni | S | P |

| ≤ 0.15 | ≤ 0.75 | 5.50~7.50 | 16.00~18.00 | 3.50~5.50 | ≤ 0.03 | ≤ 0.06 |

Mechanical Properties

| Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

| ≥ 520 | ≥ 275 | ≥55-60 | ≤183HB;≤ 100 HRB |

Physical Performance

| Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(μohm.in) |

| 7.8 | 197 | 15.7 | 16.2 | 27 |