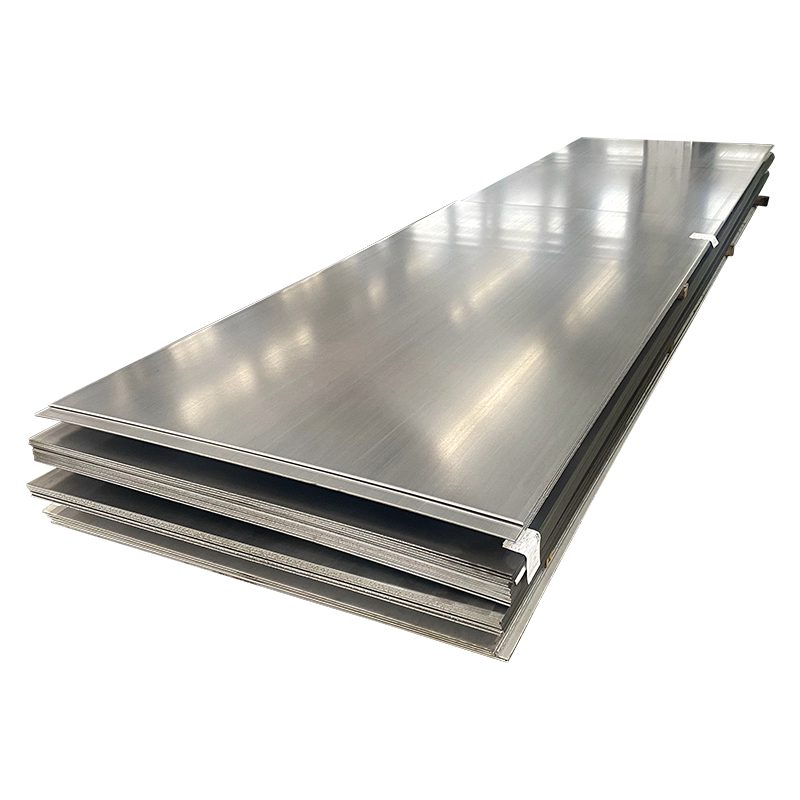

301 Stainless Steel Plate Description

301 stainless steel is a metastable austenitic stainless steel that has a complete austenitic structure under full solid solution conditions. Among stainless steels, 301 is the steel type that is most easily strengthened by cold deformation. Through cold deformation processing, the strength and hardness of the steel can be improved, and sufficient plasticity and toughness can be retained. In addition, this steel has good rust resistance under atmospheric conditions. 301 is mainly used in the cold working state for equipment parts that can withstand higher loads, reduce the weight of the equipment and make it rust-free. In addition, this steel is prone to work hardening when impacted by external forces and can absorb more impact energy, providing more reliable safety protection for equipment and personnel. However, 301 stainless steel plate has poor corrosion resistance in chemical media such as acid, alkali and salt, so it is not recommended for use in harsh corrosive environments.

Product Parameters

| Product Name | 301 Stainless Steel Plate |

| Type | Plate |

| Thickness | 0.3mm-200mm |

| Length | 2000mm, 2438mm, 3000mm, 5800mm, 6000mm, 12000mm, etc. |

| Width | 40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc. |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. |

| Surface | BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

| Scope of Application | Widely used in high temperature and electrical industry, medical equipment construction, chemical, food industry, agriculture and ship parts, food and beverage packaging, Kitchen supplies, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs and screens, etc. |

| Certificate | ISO, SGS, BV, etc. |

| Production Technology | Hot Rolling, Cold Rolling |

| Edge Processing | Edging, Trimming |

Chemical Composition

| C | Si | Mn | Cr | Ni | S | P |

| ≤ 0.15 | ≤ 1.0 | ≤ 2.0 | 16.0~18.0 | 6.0~8.0 | ≤ 0.03 | ≤ 0.045 |

Mechanical Properties

| Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

| ≥ 520 | ≥ 205 | ≥ 40 | ≤ 187HB ;≤ 90HRB;≤ 200HV |

Physical Performance

| Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(μohm.in) |

| 7.88 | 193 | 16.9 | 16.2 | 27.4 |

Surface Selection