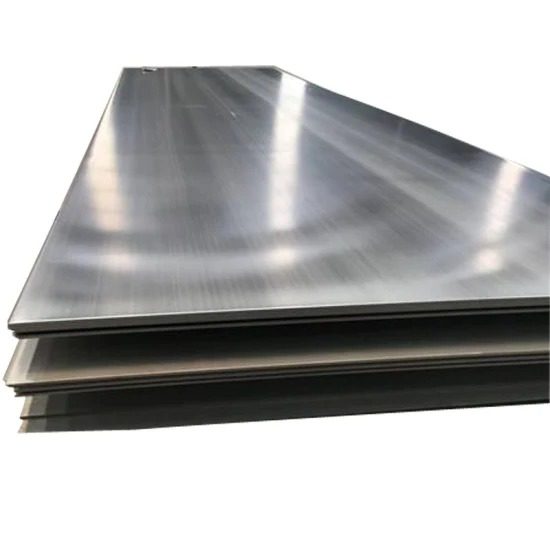

309/309S Stainless Steel Plate Description

309 stainless steel is an austenitic stainless steel containing higher chromium and nickel content. 309 stainless steel has excellent corrosion resistance in various corrosive media, including acid, alkali, salt and other solutions, as well as organic solvents. It can still maintain good corrosion resistance at high temperatures. Moreover, it has good high-temperature strength and creep properties and can work stably for a long time in high-temperature environments. It is suitable for high-temperature equipment in aviation, chemical industry and other fields. 309 stainless steel can be formed and welded through various processing methods and has good processing performance. Lastly, 309 stainless steel is non-magnetic and suitable for manufacturing parts and components without magnetic requirements.

Product Parameters

| Product Name | 309/309S Stainless Steel Plate |

| Type | Plate |

| Thickness | 0.3mm-200mm |

| Length | 2000mm, 2438mm, 3000mm, 5800mm, 6000mm, 12000mm, etc. |

| Width | 40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc. |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. |

| Surface | BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

| Scope of Application | Widely used in high temperature and electrical industry, medical equipment construction, chemical, food industry, agriculture and ship parts, food and beverage packaging, Kitchen supplies, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs and screens, etc. |

| Certificate | ISO, SGS, BV, etc. |

| Production Technology | Hot Rolling, Cold Rolling |

| Edge Processing | Edging, Trimming |

Chemical Composition

| C | Si | Mn | Cr | Ni | S | P |

| ≤ 0.08 | ≤ 0.75 | ≤ 2.0 | 22.0~24.0 | 12.0~15.0 | ≤ 0.03 | ≤ 0.045 |

Mechanical Properties

| Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

| ≥515 | ≥205 | ≥35 | ≤ 217HB |

Physical Performance

| Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(ΜΩ. cm) |

| 7.98 | 200 | 14.9 | 15.6 | 78 |

Surface Selection