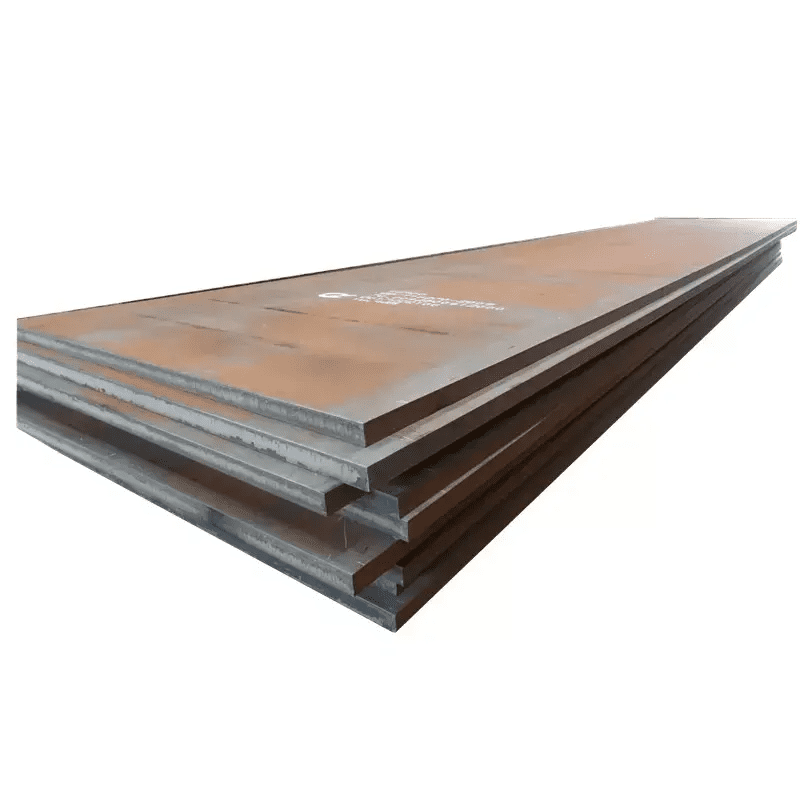

Wear Resistant Steel Plate (NM Plate) Description

A Wear-Resistant Steel Plate is made from an alloy of stainless steel that contains at least 0.2 % nickel, aluminum, or copper. It is frequently used in the manufacturing of structural components and tools. The alloy is resistant to wear, corrosion, and rust.

Steel plates that are Wear Resistant Plates are normally produced in their as-rolled condition. These steel plate product types have been created specifically for long service life in challenging environments. Tempering and quenching are used to create wear-resistant steel plates. The formation of crystal structures during the quenching process enhances the material’s strength. Steel produced using this technique has a four times greater resistance to wear.

Product Parameters

| Product Name | Wear Resistant Steel Plate (NM Plate) |

| Production Process | Cutting, Bending, Polishing, etc. |

| Common Grades | NM260, NM300, NM360,NM350, NM400, NM450, NM500, NM550, NM600, etc. |

| Width | 100mm-3500mm |

| Length | 1m-18m, or Customized Size |

| Thickness | 0.4mm-80mm |

| Surface | Oiled, Black Painted, Shot Blasted, Hot Dipped Galvanized, Checkered, etc. |

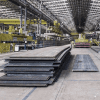

Uses of Wear Resistant Plates

Wear Resistant Steel Plates are used in the construction of buildings and bridges in addition to being used for kitchenware and appliances like cutlery and plates. Wear Resistant Plates can be used in a variety of materials, including cast iron, ductile iron, high-carbon steel, low-carbon steel, and stainless steel. These Plates are used in industries where moving components are exposed to impact and abrasion. They can be made from a variety of materials, they provide greater abrasion resistance and can help prevent metal parts from scratching.